Development perspectives for lithium-ion battery cell formats

The Fraunhofer Institutes ICT, IPA, ISI and the Fraunhofer research institution FFB have presented a study on the development of lithium-ion battery cell formats. It looks at the most important trends in battery chemistry, cell formats, cell production and safety and compares them with the requirements of various battery applications. Special attention is paid to the announcements of the automotive manufacturers, e.g. on large-format cells.

The study, which was developed in the context of the "FoFeBat" project, is an update of the Fraunhofer study "Entwicklungsperspektiven für Zellformate von Lithium-Ionen-Batterien in der Elektromobilität" published in 2017.

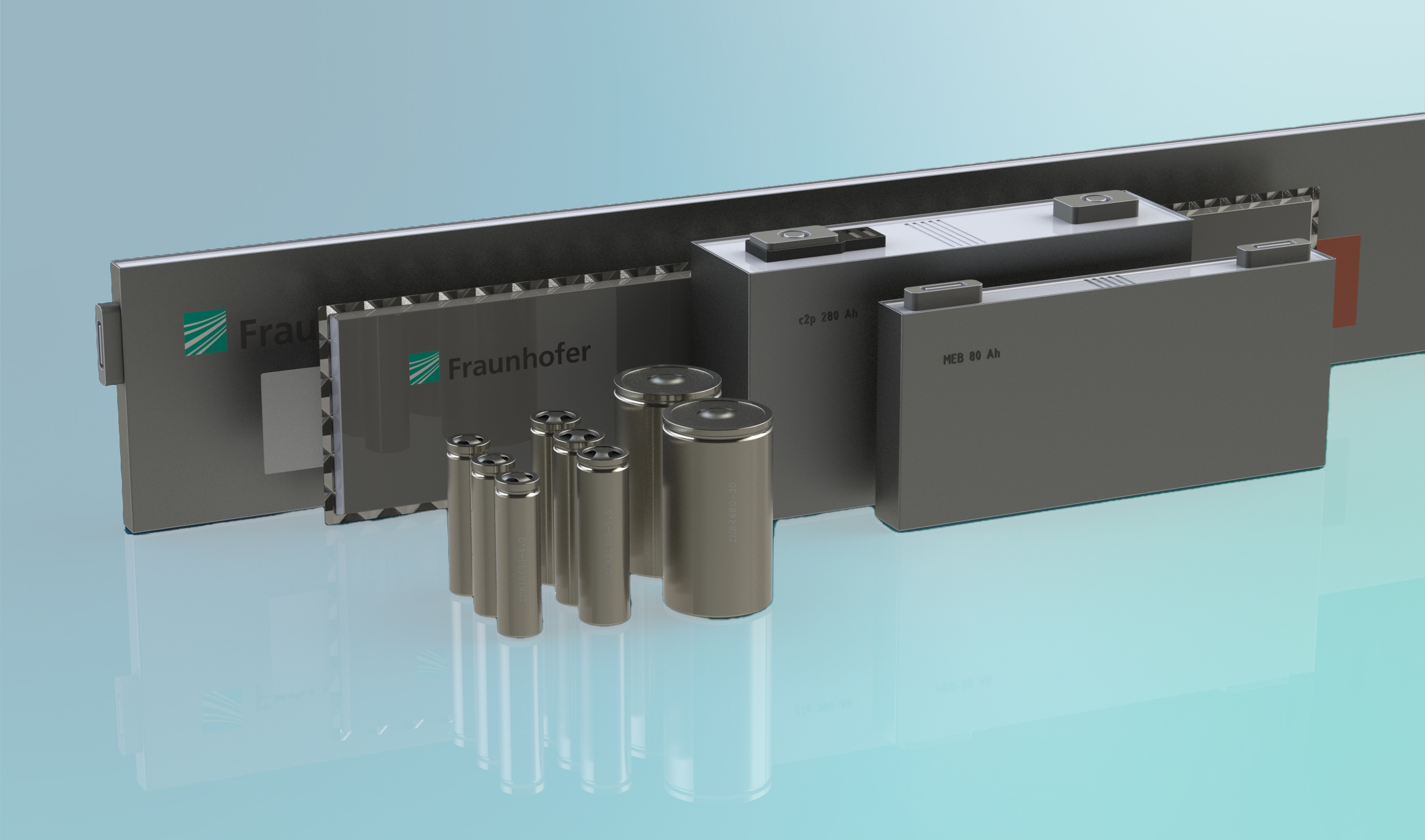

Battery cells come in various formats - the most common are prismatic, cylindrical and pouch cells. All three cell formats are found in almost all battery applications from electric cars to stationary applications and electronics. The perfect format for each application does not yet seem to have been found, although the choice of format sometimes has a significant impact on the battery's properties. Decisions made several years ago on the format or existing supply relationships between users and producers often play the dominant role in the selection.

However, with the advancing establishment of the lithium-ion battery as the energy storage system of the future, this could change. For many applications, a paradigm shift is taking place: Instead of adapting the application design to the battery, the battery design is being adapted to the application. Probably the most prominent example is the "cell to pack" concept, which envisages the integration of battery cells in the vehicle without having to assemble them in modules.

All three cell formats still have great development potential. This starts with the selection of materials, the design of the electrode and cell structure, cell production and extends to cell integration. The study "Development perspectives for lithium-ion bat-tery cell formats" addresses precisely these aspects of battery cells, describes the status quo and presents opportunities for further development.

Cost advantages through new materials and electrode stacks

New materials, both on the cathode and anode side, will continue to play an important role in increasing cell performance or further reducing cell costs. The plans of many manufacturers include the use of nickel-based (Ni) oxide materials. At the same time, iron-based (Fe) and manganese-based (Mn) materials are likely to become more widespread, enabling significant cost advantages. Silicon (Si) will also play an increasingly important role as anode material.

Advances in material design will also lead to changes at the electrode level. For example, an increase in electrode coatings to well over 100 µm can be expected in the next five to ten years. Compared with winding, the use of electrode stacks will enable the gains in energy density achieved in this way to be transferred to the cell level to an even greater extent. Particularly in the case of large-format cells, this will also have an effect on thermal and electrical coupling. In the automotive sector in particular, this applies, for example, to pouch cells up to 500 mm and prismatic cells up to 1000 mm in length.

Thanks to these technical improvements at the material and cell level, peak energy densities of up to 850 Wh/l could become possible by 2025 and up to 950 Wh/l by 2030 with conventional liquid electrolyte-based technologies. Although the energy densities of the three main cell formats will continue to converge, pouch cells are expected to remain at the forefront.

As the energy density increases, so does the potential hazard, especially for large cell formats. However, the distinction between pouch type, prismatic hard case and cylindrical format plays only a minor role in system safety. The decisive factors are the cell chemistry, the cell structure (e.g. electrode packing, gas channels), the integration of the battery pack and certain hardware- or software-related safety features.

Some technological innovations are also expected in the production of battery cells. These concern the use of digital methods in scaling and process control, but also the introduction of completely new processes such as dry coating or highly efficient formation technologies. These innovations can not only reduce costs and increase manufacturing quality, but will also have a favorable impact on the ecological footprint of the batteries - a parameter that will become even more important in the future.

The "FoFeBat" project and Fraunhofer's contribution to battery research

The study was carried out as part of the »FoFeBat« project funded by the German Federal Ministry of Education and Research BMBF. The aim of the project is to establish the Research Institution for Battery Cell Production FFB in Münster, a Fraunhofer facility that will enable research and development of battery cell production up to the GWh scale. In particular, the Fraunhofer FFB will take up technologies of high maturity and scale them up to industrial applicability.

The study, prepared jointly by the Fraunhofer research institutions and institutes FFB, ICT, IPA and ISI, thus not only provides insight into trends and challenges regarding cell formats, but at the same time identifies important R&D topics that the Fraunhofer-Gesellschaft is working on in the battery sector. The results of the study, in particular the view of developments in industry, are to be used for the further orientation of the Fraunhofer FFB and support the emerging range of services geared to the battery industry in Germany and Europe.